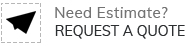

Ribbon Blender Machine

68000 INR/Piece

Product Details:

- Blade Type Inner and Outer Ribbon

- Surface Finish Mirror/Matte Polished

- Frequency 50/60 Hz

- Noise Level Low

- Motor Power 3 HP to 15 HP

- Drive Type Gearbox drive

- Mounting Type Floor Mounted

- Click to View more

X

Ribbon Blender Machine Price And Quantity

- 1 Piece

- 68000 INR/Piece

- 68000.00 - 275000.00 INR/Piece

Ribbon Blender Machine Product Specifications

- Ribbon Blender

- No

- Gearbox drive

- 3 HP to 15 HP

- 600 to 1500 kg (varies with capacity)

- Standard/Custom as per order

- Silver/Grey

- 50/60 Hz

- Mirror/Matte Polished

- Ribbon Blender Machine

- Inner and Outer Ribbon

- Horizontal

- Powder Mixing, Dry Solids Blending, Food, Chemicals, Pharmaceuticals

- 100 to 5000 Liters (customized)

- Low

- Up to 70% of total volume

- Stainless Steel (SS304/SS316)

- 380V/415V

- Floor Mounted

- Standard/Customizable

- Standard or As per requirement (e.g. 2000mm x 800mm x 1200mm)

Ribbon Blender Machine Trade Information

- 5 Piece Per Week

- 1 Week

Product Description

We are the notable manufacturer and supplier of Ribbon Blender Machine as per the application requirements of the clients. This commercial mixer is designed for homogeneous and efficient mixing of variegated formulations and ingredients. It is capable of mixing the smallest quantity of ingredient efficiently. There are curved horizontal ribbon blades to tumble and lift material in it. While conveying to the center of the mixer drum, material goes through downward and upward movements. There is a cross blending movement inside this Ribbon Blender Machine. This product is also tested on set parameters before final dispatch to the client.

Features:

- Uniform mixing and blending of powder,paste and slurries

- Strong construction

- Long functional life

- Easy to accommodate

Tailored Configuration for Diverse Processes

The Ribbon Blender Machine is designed with customizable inlet and outlet ports to align with specific process requirements. Whether your operation involves powder mixing or dry solids blending, you can choose manual or pneumatic discharge valves for controlled release. The mounting type is floor-mounted, offering stability in high-capacity industrial environments.

Superior Cleaning and Maintenance

Easy-to-remove covers and PTFE gland packing ensure simple, efficient cleaning. This reduces downtime and maintains hygiene standards, essential for pharmaceutical and food industry applications. Heavy-duty spherical roller bearings and a gearbox drive system guarantee robust, low-noise operation over extended usage.

Advanced Safety and Control Features

Safety is prioritized through integrated overload protection and an emergency stop button. For enhanced control, an operational panel is available on request, enabling precise management of mixing parameters. The machine meets cGMP design standards, ensuring reliability for regulated industries.

FAQs of Ribbon Blender Machine:

Q: How does the Ribbon Blender Machine ensure thorough and consistent mixing of powders?

A: The machine utilizes a single continuous agitator shaft fitted with inner and outer ribbon blades. This configuration provides effective radial and axial movement, ensuring homogeneous blending of powders and dry solids throughout the vessel.Q: What cleaning process should be followed after mixing operations?

A: Cleaning is straightforward due to the removable covers and PTFE gland packing design. Simply open the covers, remove any residue, and wipe down the interior with suitable cleaning agents compatible with stainless steel. The easy disassembly helps maintain hygiene, especially in food and pharmaceutical settings.Q: When should manual or pneumatic discharge valves be used?

A: Manual discharge valves are suitable for batch operations or smaller volumes where precise control is required. Pneumatic discharge valves are recommended for faster unloading and automated processes, ideal in applications with higher throughput or where efficiency is critical.Q: Where can this Ribbon Blender Machine be installed and used?

A: This machine is floor-mounted and can be installed in production facilities, laboratories, or manufacturing plants involved in powder mixing, dry solids blending, and related processes. Its widely used in sectors such as food, chemicals, pharmaceuticals, and more across India and for export.Q: What are the benefits of having customized inlet/outlet ports and capacities?

A: Customizing inlet and outlet ports allows the machine to connect seamlessly with existing process lines, minimizing spillage and optimizing workflow. Adjustable capacities from 100 to 5000 liters ensure suitability for both small-scale and large-volume production requirements.Q: How does the machine enhance operational safety and user control?

A: Safety features like overload protection and an emergency stop button protect both the operator and equipment from potential hazards. An optional operational panel provides monitoring and control of mixing speed and process parameters, enhancing user convenience.Q: What advantages does the use of stainless steel (SS304/SS316) provide?

A: Stainless steel construction ensures excellent corrosion resistance, durability, and compliance with sanitary regulations. The mirror or matte polished surface finish enhances cleanliness and prevents product contamination, making it ideal for pharmaceutical and food-grade applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Ribbon Blender' category

|

THIRUMALAI INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese