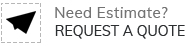

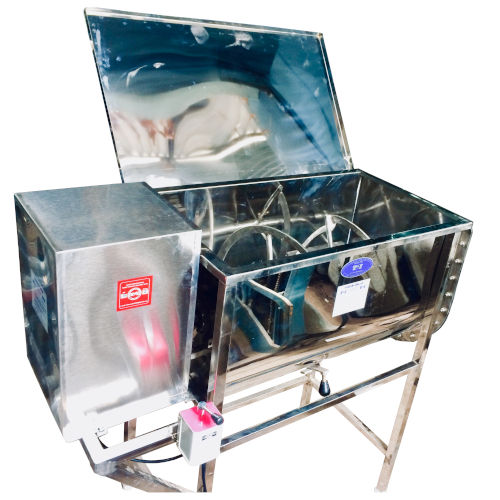

Ribbon Mixer Machines

Product Details:

- Motor Power 5 HP Horsepower (HP)

- Surface Finish Polished

- Drive Type Gearbox Drive

- Frequency 50/60 Hz Hertz (HZ)

- Noise Level 75 db db

- Mixing Speed 18-35 rpm RPM

- Features Easy to Operate, Uniform Mixing, Low Maintenance

- Click to View more

Ribbon Mixer Machines Price And Quantity

- 1 Unit

- 78000 INR/Unit

Ribbon Mixer Machines Product Specifications

- No

- 5 HP Horsepower (HP)

- Polished

- Approx. 480 kg Kilograms (kg)

- Standard & Customized

- U-shaped

- 250 - 5000 kg/batch Kg

- Horizontal Ribbon Blender

- Gearbox Drive

- No

- Ribbon Mixer Machine

- 1500 x 800 x 1200 mm Millimeter (mm)

- 50/60 Hz Hertz (HZ)

- Semi-Automatic

- Stainless Steel

- 75 db db

- 220-440 V Volt (v)

- Easy to Operate, Uniform Mixing, Low Maintenance

- 18-35 rpm RPM

- Double Helical Ribbon

- Powder & Granule Mixing

- 5-15 kW Watt (w)

- Horizontal

- Silver

Ribbon Mixer Machines Trade Information

- 20 Unit Per Month

- 1 Week

- All India

Product Description

We are offering the U Type Blender Machine for use in various commercial and industrial applications. They are very easy to use and made using stainless steel. It is very easy to operate and install. The offered blender has a high capacity and is very effective. It is very efficient and helps in blending of various items. The offered blender is a U Type Blender Machine made high end performance. The blender is very uniquely designed and made for an easier and smooth functioning. The offered blender is made for use in various places and is absolutely safe.

Consistent, Homogeneous Blending

Achieve over 97% uniformity in your batch with the specially designed double helical ribbon blade. Its U-shaped tank and customizable dimensions allow efficient, gentle mixing for powders and granules, minimizing segregation and improving product consistency every cycle.

Built for Longevity and Hygiene

With a polished stainless-steel surface, food-grade rubber gaskets, and optional PTFE/Teflon lining, the Ribbon Mixer is engineered for safety, cleanliness, and a service life exceeding 10 years. The manual or CIP (custom) cleaning method ensures adaptability to high hygiene standards across diverse industries.

User-Centric, Safe Operation

Equipped with emergency stop, overload protection, and intuitive controls, the machine prioritizes operator safety and simplicity. The addition of a manhole, input hopper, and floor-mounted setup promotes straightforward usage and maintains safety protocols throughout operation.

| Material | Stainless steel |

| Shape | U type |

| Design Type | Customized, Standard |

| Automation Grade | Semi-Automatic |

| Voltage | 220V - 440V/50Hz - 60Hz |

| Power | 0.75-7.5kW |

| Size | 60x30x60 inch |

FAQs of Ribbon Mixer Machines:

Q: How does the Ribbon Mixer Machine ensure uniform mixing of powders and granules?

A: The Ribbon Mixer Machine uses a double helical ribbon blade within a U-shaped tank to create a balanced axial and radial mixing motion. This design ensures over 97% homogeneous blending for batch sizes ranging from 250 kg to 5000 kg.Q: What safety features are incorporated in the Ribbon Mixer Machine?

A: The mixer is equipped with overload protection and an emergency stop button to ensure operator safety. These features help prevent equipment damage and protect users during the mixing process.Q: When is cleaning required, and what are the available cleaning methods?

A: Cleaning is recommended after each batch or when changing products. The machine supports manual cleaning as standard, and a CIP (Clean-In-Place) system can be provided as a custom option, ensuring adaptability to strict hygiene requirements.Q: Where can the Ribbon Mixer Machine be installed and used?

A: This mixer is floor-mounted and suitable for installation in food, chemical, pharmaceutical, and allied industries where powder or granule blending is required. Its design accommodates both standard and customized sizes to fit specific spatial needs.Q: What is the process for operating the Ribbon Mixer Machine?

A: Operation involves loading product through the input hopper (up to 70% of tank volume), setting the control panel for start/stop and timer (if installed), and monitoring the batch for 10-15 minutes. The bottom discharge valve allows for efficient emptying post-mixing.Q: Can the Ribbon Mixer handle high-temperature materials or sensitive products?

A: The machine operates efficiently up to 60C and offers optional PTFE/Teflon lining, making it suitable for temperature-sensitive and sticky materials, maintaining product integrity and preventing contamination.Q: What are the main benefits of choosing this Ribbon Mixer Machine for industrial use?

A: Key benefits include high batch output with consistent quality, easy operation, minimal maintenance, robust safety features, and a service life of over 10 yearsmaking it a valuable investment for bulk and precision mixing operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Ribbon Blender' category

|

THIRUMALAI INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese