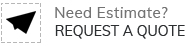

Jacketed Ribbon Blender

52000.00 INR/Unit

Product Details:

- Application Powder, Dry Blend, Pharmaceuticals, Food, Chemicals

- Frequency 50/60 Hz Hertz (HZ)

- Drive Type Direct / Chain Driven

- Blade Type Double Helical Ribbon

- Noise Level <80 dB db

- Features Jacketed, Efficient Mixing, Easy Discharge

- Motor Power 7.5 HP Horsepower (HP)

- Click to View more

X

Jacketed Ribbon Blender Price And Quantity

- 1 Unit

- 52000.00 INR/Unit

Jacketed Ribbon Blender Product Specifications

- Ribbon Blender

- Customizable (Standard: 700 mm) Millimeter (mm)

- Jacketed for Heating/Cooling

- Powder, Dry Blend, Pharmaceuticals, Food, Chemicals

- Semi-Automatic

- 50/60 Hz Hertz (HZ)

- 2200 x 700 x 1100 mm Millimeter (mm)

- Double Helical Ribbon

- Direct / Chain Driven

- Silver

- Stainless Steel (SS 304/316)

- U-shaped Horizontal

- Standard/Custom Built

- Mirror / Matt Finish

- Jacketed, Efficient Mixing, Easy Discharge

- <80 dB db

- 7.5 HP Horsepower (HP)

- 415 V Volt (v)

- Horizontal

- Approx. 750 kg Kilograms (kg)

- 500 Litre Ltr

- No

- Jacketed Ribbon Blender

Jacketed Ribbon Blender Trade Information

- 20 Unit Per Month

- 1 Week

- All India

Product Description

We are offering the U Type Blender Machine for use in various commercial and industrial applications. They are very easy to use and made using stainless steel. It is very easy to operate and install. The offered blender has a high capacity and is very effective. It is very efficient and helps in blending of various items. The offered blender is a U Type Blender Machine made high end performance. The blender is very uniquely designed and made for an easier and smooth functioning. The offered blender is made for use in various places and is absolutely safe.Superior Mixing Efficiency

Equipped with a double helical ribbon, this blender ensures consistent mixing of powders and dry materials. The U-shaped horizontal tank, direct or chain drive, and 36 rpm mixing speed are engineered to optimize blending results, minimizing dead spots and ensuring rapid homogenization of ingredients.

Flexible Temperature Control

The jacketed design enables precise temperature regulation with media such as steam, hot water, or chilled water. Capable of withstanding temperatures up to 200C, the system supports processes requiring both heating and cooling for sensitive pharmaceutical, chemical, or food applications.

User-Friendly Design & Safety

Featuring a hinged or removable lid with optional view glass, emergency stop button, and overload relay, the blender prioritizes safety and operational convenience. Cleaning is simple with provisions for spray balls or manual access, and all contact surfaces are finished in mirror or matt for easy maintenance.

FAQs of Jacketed Ribbon Blender:

Q: How is the working volume of the Jacketed Ribbon Blender determined?

A: The working volume typically ranges from 60% to 65% of the total vessel capacity (500 litres), ensuring effective blending without overfilling and maintaining optimal mixing dynamics.Q: What are the main benefits of using a jacketed ribbon blender in pharmaceutical or food processing?

A: This blender provides homogeneous mixing, efficient heat transfer through its jacket for heating/cooling, easy discharge via butterfly or slide gate valves, and can meet GMP/CE certification for hygiene and safety.Q: What cleaning and maintenance options are available?

A: Cleaning is facilitated by provisions for spray balls that allow internal rinsing or manual access for thorough inspection. Mirror or matt surface finishes also simplify cleaning and reduce residue retention.Q: When should I use oil seal versus mechanical seal on the shaft?

A: Oil seals are suitable for standard powder blending with minimal risk of leakage, while mechanical seals are recommended when the process involves hazardous materials or strict containment is needed.Q: Where can the blender be installed, and what are its mounting options?

A: This unit is designed for floor mounting and is ideal for installation in production facilities that require robust, horizontal mixing solutions, with customizable size options to fit available space.Q: What process media can be used for jacket heating or cooling?

A: The blenders jacket accommodates steam, hot water, or chilled water as process media, enabling precise temperature control tailored to product requirements.Q: How does the control panel enhance operational safety?

A: The control panel features on/off push buttons, overload protection, and an emergency stop, allowing operators to manage processes securely and respond quickly to faults or emergencies.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Ribbon Blender' category

|

THIRUMALAI INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese