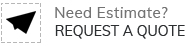

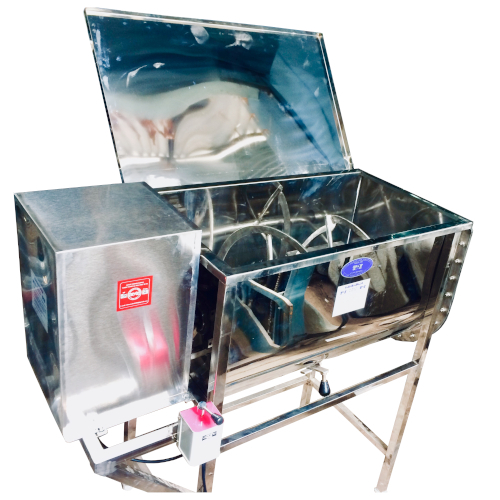

Double Ribbon Mixer

78000 INR/Unit

Product Details:

- Drive Type Gearbox Driven

- Noise Level < 70 dB db

- Blade Type Double Helical Ribbon

- Application Dry Powder, Chemicals, Pharmaceuticals, Food

- Orientation Horizontal

- Mixing Speed 36 RPM RPM

- Voltage 380 V Volt (v)

- Click to View more

X

Double Ribbon Mixer Price And Quantity

- 78000 INR/Unit

- 1 Unit

Double Ribbon Mixer Product Specifications

- Double Helical Ribbon

- 2100 x 800 x 1250 mm Millimeter (mm)

- Dry Powder, Chemicals, Pharmaceuticals, Food

- Horizontal

- No

- Horizontal

- 36 RPM RPM

- Semi-Automatic

- No

- Rectangular U Shape

- Metallic Silver

- Gearbox Driven

- Double Ribbon Mixer

- Approx. 800 mm Millimeter (mm)

- < 70 dB db

- Efficient homogeneous mixing, easy to clean

- Polished

- Customizable

- 5 HP Horsepower (HP)

- 5.5 kW Watt (w)

- 920 kg Kilograms (kg)

- 50 Hz Hertz (HZ)

- 380 V Volt (v)

- 500 Kg/batch Kg

- Stainless Steel

Double Ribbon Mixer Trade Information

- 20 Unit Per Month

- 1 Week

- All India

Product Description

We are offering the U Type Blender Machine for use in various commercial and industrial applications. They are very easy to use and made using stainless steel. It is very easy to operate and install. The offered blender has a high capacity and is very effective. It is very efficient and helps in blending of various items. The offered blender is a U Type Blender Machine made high end performance. The blender is very uniquely designed and made for an easier and smooth functioning. The offered blender is made for use in various places and is absolutely safe.Designed for Efficiency and Hygiene

With its dust-tight sealing and polished stainless steel surfaces, this mixer maintains exceptional hygiene and minimizes contamination risks. Batch cycles of just 515 minutes ensure rapid, homogeneous blending, while the heavy-duty sealed bearings provide maintenance-free lifetime lubrication.

Customizable and Easy to Operate

Available with a removable lid, safety interlock, CIP system, and customization options for heating or cooling, this mixer adapts readily to your processing needs. The intuitive control panel supports straightforward operation, and the floor-mounted design ensures stability during mixing.

| Material | Stainless steel |

| Shape | U type |

| Design Type | Customized, Standard |

| Automation Grade | Semi-Automatic |

| Voltage | 220V - 440V/50Hz - 60Hz |

| Power | 0.75-7.5kW |

| Size | 60x30x60 inch |

FAQs of Double Ribbon Mixer:

Q: How does the Double Ribbon Mixer ensure homogeneous mixing of ingredients?

A: The mixer uses double helical ribbons that rotate within a U-shaped horizontal tank. This unique blade design creates a counter-current flow, ensuring that materials are thoroughly and quickly blended for a consistent, homogeneous result in each batch.Q: What safety features are incorporated into the mixer?

A: Safety is prioritized with features like a removable lid with optional interlock, emergency stop button, and overload protection. The start/stop control panel is user-friendly, while sealed bearings and dust-tight construction further minimize operational risks.Q: When should I use the Clean In Place (CIP) system?

A: The optional CIP system is recommended when frequent changeovers between batches or stringent hygiene standards are required, such as in pharmaceutical or food processing. It allows for fast, effective cleaning without the need for disassembly.Q: Where is the Double Ribbon Mixer typically used?

A: This mixer is widely utilized in sectors like food manufacturing, pharmaceuticals, chemicals, and dry powder processing. Its stainless steel construction and hygienic design make it suitable for various industrial environments throughout India and abroad.Q: What are the discharge options available and how do they benefit the process?

A: The mixer offers pneumatic or manual discharge valves, making it easy to unload mixed products efficiently. Pneumatic discharge is ideal for automated systems, while manual valves suit operations requiring more control.Q: How easy is it to clean and maintain the mixer?

A: Thanks to features such as a removable lid, easy-to-access internal surfaces, polished finish, and sealed-for-life bearings, cleaning and maintenance are straightforward. Optional CIP further reduces downtime between batches.Q: What are the benefits of using a semi-automatic double ribbon mixer for batch processing?

A: Users benefit from rapid, uniform mixing, high hygiene standards, easy cleaning, and reliable operation. Its customizable features and robust construction ensure adaptability and long-term performance for diverse industrial applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Ribbon Blender' category

|

THIRUMALAI INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese