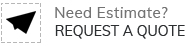

Industrial Ribbon Mixer

Product Details:

- Features Heavy-duty construction, uniform mixing

- Mounting Type Floor Mounted

- Blade Type Double Ribbon

- Noise Level Low

- Application Powder Mixing, Food, Chemicals, Pharma

- Mixing Speed 36 RPM

- Orientation Horizontal

- Click to View more

Industrial Ribbon Mixer Price And Quantity

- 1 Unit

- 52000.00 - 245000.00 INR/Unit

- 52000.00 INR/Unit

- Removable End Covers

- Ambient

- 15-20 Minutes

- Top Manhole

- Safety cover with interlocks

- On-site Service Available

- Bottom Discharge with Valve

- Mechanical Seal

- Provided

Industrial Ribbon Mixer Product Specifications

- Industrial Ribbon Mixer

- Silver

- Powder Mixing, Food, Chemicals, Pharma

- 36 RPM

- Horizontal

- Gearbox

- 5 HP

- 500 kg/batch

- 60% of tank volume

- Semi-Automatic

- 415 V

- Polished

- 5 HP

- No

- 50 Hz

- Stainless Steel

- 30 Inch

- Approx. 500 kg

- Heavy-duty construction, uniform mixing

- No

- 60 x 30 x 60 Inch

- Double Ribbon Blender

- Floor Mounted

- Low

- 60 x 30 x 60 Inch

- U-Shape

- Double Ribbon

- Removable End Covers

- Ambient

- 15-20 Minutes

- Top Manhole

- Safety cover with interlocks

- On-site Service Available

- Bottom Discharge with Valve

- Mechanical Seal

- Provided

Industrial Ribbon Mixer Trade Information

- 20 Unit Per Month

- 1 Week

- All India

Product Description

We are offering the U Type Blender Machine for use in various commercial and industrial applications. They are very easy to use and made using stainless steel. It is very easy to operate and install. The offered blender has a high capacity and is very effective. It is very efficient and helps in blending of various items. The offered blender is a U Type Blender Machine made high end performance. The blender is very uniquely designed and made for an easier and smooth functioning. The offered blender is made for use in various places and is absolutely safe.

Product details

|

Minimum Order Quantity |

1 Piece |

|

Power Required |

0.75 - 7.5 kW |

|

Voltage |

220 V - 440 V / 50 Hz - 60 Hz |

|

Capacity |

50 kg - 1000 kg |

|

Application |

For Mixing Chemical, Ayurvedic Medicine & Food Products( Spice Powders) |

|

Material |

Stainless Steel |

|

Size |

60 x 30 x 60 Inch |

Superior Mixing Performance

Equipped with a double ribbon blade and a 36 RPM operating speed, this industrial mixer achieves thorough blending of powders. The heavy-duty design supports batch sizes up to 500 kg, making it ideal for bulk processing in diverse sectors. The 60% loading capacity optimizes operational efficiency, while the polished stainless steel surface ensures easy cleaning and product integrity.

Enhanced Safety and Maintenance

User safety is prioritized with a cover fitted with interlock mechanisms to prevent accidental operation. Removable end covers facilitate hassle-free cleaning and maintenance. The bottom discharge valve and mechanical seal contribute to secure, leak-free operation, supported by a visible level indicator and ambient temperature handling for versatile process control.

Installation and Service Support

The mixer is designed for straightforward, floor-mounted installation. Our team offers comprehensive on-site installation and service across India, ensuring smooth setup and ongoing reliability. The compact dimensions and horizontal orientation allow for efficient integration into existing production lines, supported by low power consumption and minimal noise output.

FAQs of Industrial Ribbon Mixer:

Q: How is product discharge managed in this ribbon mixer?

A: The mixer utilizes a bottom discharge system fitted with a valve, enabling efficient and controlled removal of mixed materials. This design minimizes spillage and ensures quick batch transitions during production.Q: What safety features does the mixer offer to users?

A: A safety cover equipped with interlocks prevents operation when the cover is open, reducing risk during maintenance or loading. This enhances operator safety and helps meet regulatory requirements.Q: When and how should the cleaning procedure be conducted?

A: After each batch or when changing product types, cleaning is recommended. The removable end covers allow easy access for thorough sanitation, supporting hygienic operations, especially in food and pharmaceutical applications.Q: What materials or industries are suitable for this ribbon mixer?

A: This mixer is ideal for powder mixing tasks in food, chemical, and pharmaceutical industries, thanks to its robust stainless steel build, uniform mixing capability, and easy cleaning features.Q: Where is installation and service support available for the mixer?

A: On-site installation and technical service are available throughout India, ensuring that customers receive prompt setup assistance and maintenance support directly at their facility.Q: How does the industrial ribbon mixer ensure uniform mixing?

A: The double ribbon blade design and calculated mixing speed (36 RPM) create a counter-current flow of materials within the U-shaped tank, promoting consistent and thorough blending for each batch.Q: What are the primary benefits of using this industrial ribbon mixer?

A: Users benefit from heavy-duty construction, reliable safety systems, rapid mixing times (1520 minutes per batch), low operational noise, and straightforward cleaning and maintenance, contributing to efficiency and product quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Ribbon Blender' category

|

THIRUMALAI INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese