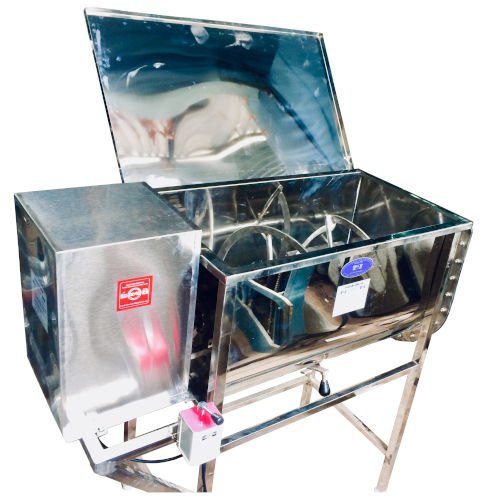

Ribbon Blender Machine

Product Details:

- Application Powder, Granules, Spices, Chemicals, Food Processing

- Motor Power 10 HP Horsepower (HP)

- Voltage 415 V Volt (v)

- Mixing Speed 36 rpm RPM

- Features Uniform Mixing, Easy Operation, Low Maintenance

- Frequency 50 Hz Hertz (HZ)

- Orientation Horizontal

- Click to View more

Ribbon Blender Machine Price And Quantity

- 78000 INR/Unit

- 1 Unit

Ribbon Blender Machine Product Specifications

- 7500 W Watt (w)

- Silver

- 50 Hz Hertz (HZ)

- Uniform Mixing, Easy Operation, Low Maintenance

- No

- 500 kg/batch Kg

- 36 rpm RPM

- 700 mm Millimeter (mm)

- 2200 x 700 x 1200 mm Millimeter (mm)

- Stainless Steel

- 10 HP Horsepower (HP)

- 415 V Volt (v)

- Ribbon Blender Machine

- 850 kg Kilograms (kg)

- Powder, Granules, Spices, Chemicals, Food Processing

- Automatic

- Gearbox Drive

- Double Helical Ribbon

- No

- Less than 75 dB db

- Ribbon Mixer

- U-Shaped

- Mirror Polish

- Customizable

- Horizontal

Ribbon Blender Machine Trade Information

- 20 Unit Per Month

- 1 Week

- All India

Product Description

We are offering the U Type Blender Machine for use in various commercial and industrial applications. They are very easy to use and made using stainless steel. It is very easy to operate and install. The offered blender has a high capacity and is very effective. It is very efficient and helps in blending of various items. The offered blender is a U Type Blender Machine made high end performance. The blender is very uniquely designed and made for an easier and smooth functioning. The offered blender is made for use in various places and is absolutely safe.

Precision Mixing for Diverse Applications

Engineered for flexibility, the Ribbon Blender Machine accommodates a wide variety of products such as powders, granules, and spices. Its customizable SS304 or SS316 contact surfaces, double helical ribbon blades, and U-shaped tank guarantee gentle yet thorough mixing. The automatic operation and floor-mounted design offer a powerful solution for food processing, chemical, and pharmaceutical manufacturing.

Effortless Cleaning and Reliable Operation

The model supports manual or optional CIP (Clean-In-Place) cleaning methods, ensuring hygiene compliance and ease of maintenance. The dustproof gasket seals and mirror-polished surfaces minimize product contamination and residue retention. With reliable gearbox drive and optional PLC controls, the machine provides stable, efficient, and repeatable performance with minimal supervision.

Safe and Energy-Efficient Performance

Safety features such as manhole access with a safety grid and robust construction ensure operational security. The blender operates efficiently within a 0C to 60C temperature range, consuming minimal energy and generating less than 75 dB of noise. This ensures a safe and cost-effective mixing process, making it suitable for continuous industrial use.

| Material | Stainless steel |

| Shape | U type |

| Design Type | Customized, Standard |

| Automation Grade | Semi-Automatic |

| Voltage | 220V - 440V/50Hz - 60Hz |

| Power | 0.75-7.5kW |

| Size | 60x30x60 inch |

FAQs of Ribbon Blender Machine:

Q: How does the Ribbon Blender Machine ensure uniform mixing for different batch sizes?

A: The machine uses a double helical ribbon blade system inside a U-shaped, mirror-polished tank. This design ensures all materials are thoroughly mixed by moving them both radially and laterally, which is effective for a wide range of batch sizes up to 500 kg.Q: What maintenance is required for the Ribbon Blender Machine, and how easy is it to clean?

A: The blender is designed for low maintenance, with durable SS304/SS316 contact surfaces and dustproof gasket seals. Cleaning is straightforward, with manual access through a manhole and optional CIP (Clean-In-Place) for enhanced convenience and hygiene.Q: When should the bottom discharge valve be used during operations?

A: The bottom discharge valve is used after the completion of each mixing cycle to efficiently empty the mixed product. Its dustproof gasket seals help prevent spillage and minimize dust during discharge, ensuring cleaner operations.Q: Where can this Ribbon Blender Machine be installed in a production facility?

A: With its floor-mounted orientation and compact dimensions (2200 x 700 x 1200 mm), the blender is suitable for various industrial environments, including food, chemical, spice, and pharmaceutical production lines in India and globally.Q: What benefits does the PLC-based optional control panel offer?

A: The PLC-based control panel allows operators to automate and precisely control mixing parameters such as batch timing and mixing speed, resulting in increased accuracy, repeatability, and productivity.Q: How does the machine contribute to energy efficiency and low operational costs?

A: Operating at 7500 W with a 10 HP motor, the ribbon blender is engineered for low energy consumption, requiring minimal power for its capacity. Its robust gearbox drive and efficient mixing design reduce batch times and operational expenses.Q: What safety features are integrated into the Ribbon Blender Machine?

A: Safety is enhanced with a manhole equipped with a safety grid for secure access, dustproof gaskets to prevent leaks, and a noise level kept below 75 dB. These features support a safer work environment for operators.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Ribbon Blender' category

|

THIRUMALAI INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese