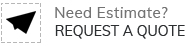

Ribbon Dryer

78000 INR/Unit

Product Details:

- Voltage 220 - 440 Volt (v)

- Type Ribbon Blender

- Material Stainless Steel

- Computerized No

- Automatic Grade Semi-Automatic

- Power(W) 0.75-7.5 Watt (w)

- Size 60x30x60 inch

- Click to View more

X

Ribbon Dryer Price And Quantity

- 78000 INR/Unit

- 1 Unit

Ribbon Dryer Product Specifications

- Ribbon Blender

- 60x30x60 inch

- 220 - 440 Volt (v)

- No

- Silver

- Semi-Automatic

- 1 Year

- Stainless Steel

- 0.75-7.5 Watt (w)

Ribbon Dryer Trade Information

- 20 Unit Per Month

- 1 Week

- All India

Product Description

We are offering the U Type Blender Machine for use in various commercial and industrial applications. They are very easy to use and made using stainless steel. It is very easy to operate and install. The offered blender has a high capacity and is very effective. It is very efficient and helps in blending of various items. The offered blender is a U Type Blender Machine made high end performance. The blender is very uniquely designed and made for an easier and smooth functioning. The offered blender is made for use in various places and is absolutely safe.High-Quality Stainless Steel Construction

Crafted with premium-grade stainless steel, the Ribbon Dryer ensures durability and resistance to corrosion, making it an ideal choice for industries that require consistent hygiene and long-term operation. Its robust build supports demanding workflows while maintaining a sleek silver finish that is easy to clean and maintain.

Efficient Mixing and Drying

Utilizing a ribbon blender design, this semi-automatic dryer evenly mixes and dries materials, enhancing process efficiency and product consistency. The machine is suitable for a range of applications, from food processing to pharmaceuticals, thanks to its large interior and Even Heat Distribution.

FAQ's of Ribbon Dryer:

Q: How does the Ribbon Dryer operate and what is its primary use?

A: The Ribbon Dryer uses a semi-automatic ribbon blender mechanism to efficiently blend and dry bulk materials. It is primarily used in the chemical, pharmaceutical, and food processing industries for uniform mixing and moisture removal from products.Q: What is the typical process for drying materials with this machine?

A: Materials are loaded into the stainless steel chamber, where the ribbon blades move the materials in a convective motion, promoting thorough mixing and exposure to drying air or heat. This process continues until the desired dryness and uniformity are achieved.Q: When should the Ribbon Dryer be chosen over other drying equipment?

A: The Ribbon Dryer is ideal when consistent blending and simultaneous drying are essential, especially for powders, granules, or slurry-type materials. Its robust design and moderate power range suit medium- to large-scale production environments.Q: Where is the Ribbon Dryer commonly used or installed?

A: This equipment is widely utilized in manufacturing plants across India, particularly in industries such as pharmaceuticals, food processing, and specialty chemicals, due to its versatile application, efficiency, and easy installation.Q: What are the benefits of using this semi-automatic Ribbon Dryer?

A: Benefits include uniform product quality, time-saving operations, low maintenance due to lack of computerized parts, and corrosion resistance from its stainless steel body. A one-year warranty provides added reassurance on product reliability.Q: How should the Ribbon Dryer be maintained for optimal performance?

A: Routine cleaning of the ribbon and chamber, regular checks for mechanical wear, and ensuring appropriate voltage supply help maintain efficient operation. As a non-computerized unit, maintenance is generally straightforward and cost-effective.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Ribbon Blender' category

|

THIRUMALAI INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese