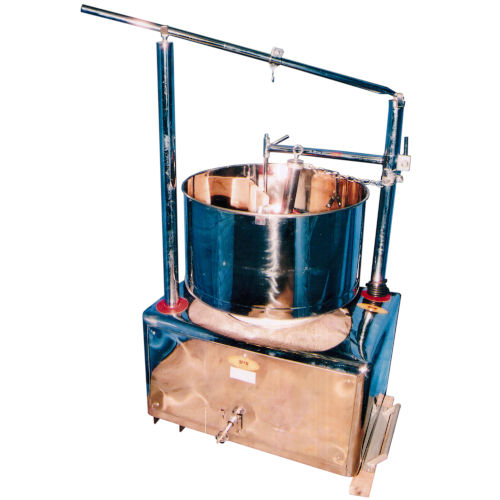

Rice Batter Grinding Machine

Product Details:

- Power Supply Manually

- Features Good quality

- Material Stainless Steel

- Power Source Electric

- Use Hotel

- Shape Rectangle

- Click to View more

Rice Batter Grinding Machine Price And Quantity

- 16500 INR/Unit

- 1 Unit

Rice Batter Grinding Machine Product Specifications

- Manually

- Good quality

- Stainless Steel

- Electric

- Hotel

- Rectangle

Rice Batter Grinding Machine Trade Information

- 20 Unit Per Month

- 1 Week

Product Description

Conventional Wet Grinder

We are a remarkable entity engaged in offering superior range of Conventional Wet Grinder that is extensively used in restaurants, hotels, canteens, hostels, bakeries, and functions. This precision designed grinder has stone type stainless steel body for ensuring greater durability and robustness, high efficiency and rapid in grinding. Our offered Conventional Wet Grinder is available in various specifications and can be customized as per the needs of the clients and at reasonable prices.

- Our range of Conventional Grinders is used in hotels, restaurants, canteens, bakeries, hostels.

- We are engaged in manufacturing a wide range of conventional grinders, having stone type, stainless steel body.

- Extremely efficient and fast in grinding as conventional method.

- This type of machine long lasting and cost effective.

Features:

- Fine quality

- Requires low maintenance

- Corrosion proof

- Sturdy structure

Technical Specification

|

Capacity(Litre) |

3 |

5 |

7 |

10 |

15 |

20 |

|

Motor Capacity |

0.5 hp |

0.75 hp |

1 hp |

1.5 hp |

2 hp |

3 hp |

|

Weight |

90 kg |

125 kg |

135 kg |

155 kg |

185 kg |

250 kg |

|

Sizes(Inch) |

34x22x36 |

35x25x42 |

35x25x44 |

39x28x48 |

39x40x49 |

Lift model |

|

Utility |

Grinds(WET) Rice, Dhal, Masala, Chuttney, etc., |

|||||

Efficient and Durable Grinding Solution

This grinding machine stands out for its high efficiency and long-lasting performance. Crafted from premium stainless steel, it resists corrosion and maintains hygiene-a crucial factor in food processing for hotels and commercial kitchens. Its rectangular design ensures stability during operation, making large quantities of batter with ease.

Ideal for Commercial Use Across India

Specially tailored for hotels, exporters, manufacturers, and suppliers, this battery grinding machine meets the demands of large-scale food production. Its electric operation guarantees consistent power supply, enabling users from all corners of India to benefit from reliable and swift grinding processes.

FAQ's of Rice Batter Grinding Machine:

Q: How does the rice batter grinding machine operate with a manual power supply and electric power source?

A: The machine primarily uses an electric power source for efficient grinding, ensuring consistent performance. However, certain manual components allow for specific adjustments or operational controls, enhancing user flexibility.Q: What makes the stainless steel material ideal for this grinding machine?

A: Stainless steel is chosen for its durability, resistance to rust and corrosion, and easy cleaning. These qualities ensure the machine remains hygienic and lasts longer, making it suitable for the rigorous demands of hotels and commercial kitchens.Q: When should I use this machine for rice batter preparation in a hotel setting?

A: It is best used whenever large quantities of rice batter are needed, such as during peak meal preparation times, breakfast rushes, or events. Its high capacity and consistent grinding make it ideal for busy hotel kitchens.Q: Where can I source this rice batter grinding machine in India?

A: You can procure this machine directly from leading exporters, manufacturers, and suppliers specializing in kitchen equipment across India. Many offer after-sales support and timely delivery for your convenience.Q: What is the process for grinding rice batter using this machine?

A: Simply load the desired amount of rice into the hopper, switch on the electric power source, and let the machine grind the rice into a smooth batter. The design ensures a uniform grind and quick processing, saving time and effort.Q: What are the main benefits of using this rice batter grinding machine?

A: Key benefits include high-quality, uniform batter production, increased efficiency, reduced manual labor, and enhanced hygiene due to the stainless steel construction. It is especially advantageous for large-scale operations in hotels and commercial establishments.Q: How can this grinding machine improve the usage experience for exporters and manufacturers?

A: The machine's robust build, efficient performance, and easy maintenance contribute to streamlined operations, reducing downtime and ensuring consistent quality-key factors for exporters and manufacturers seeking reliable food processing solutions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Wet Grinders' category

|

THIRUMALAI INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese